Welcome to Fagus-GreCon - preventive fire protection for your company.

- Our solutions

- Components

- Our service

Do you have questions about our solutions, industries and areas of application? Get to know Fagus-GreCon and see for yourself. Preventive fire protection also protects your company's assets.

LEARN MOREOur fire protection solutions can be used in various industries and applications - including for your requirements.

LEARN MORE- Industries

Our industry-specific solutions form the basis for successful measurement technology applications in your company.

LEARN MORE

- CHEMICALS

- Chemical Industry

- Hygiene industry

- WOOD-BASED MATERIALS

- MDF Industry

- OSB Industry

- Pellet Industry

- Particle Board Industry

- Plywood Industry

- Power Plant Industry

- FOOD

- Food Industry

- Animal Feed Industry

- Coffee Industry

- Cocoa Industry

- Flour Production Industry

- Sugar Industry

- METALS

- Metallindustrie

- Automotive Industry

- RECYCLING

- Recycling Industry

- Tire Recycling

- PROCESSING

- Furniture Industry

- Paper Industry

- Textile Industry

- Nonwoven fabrics

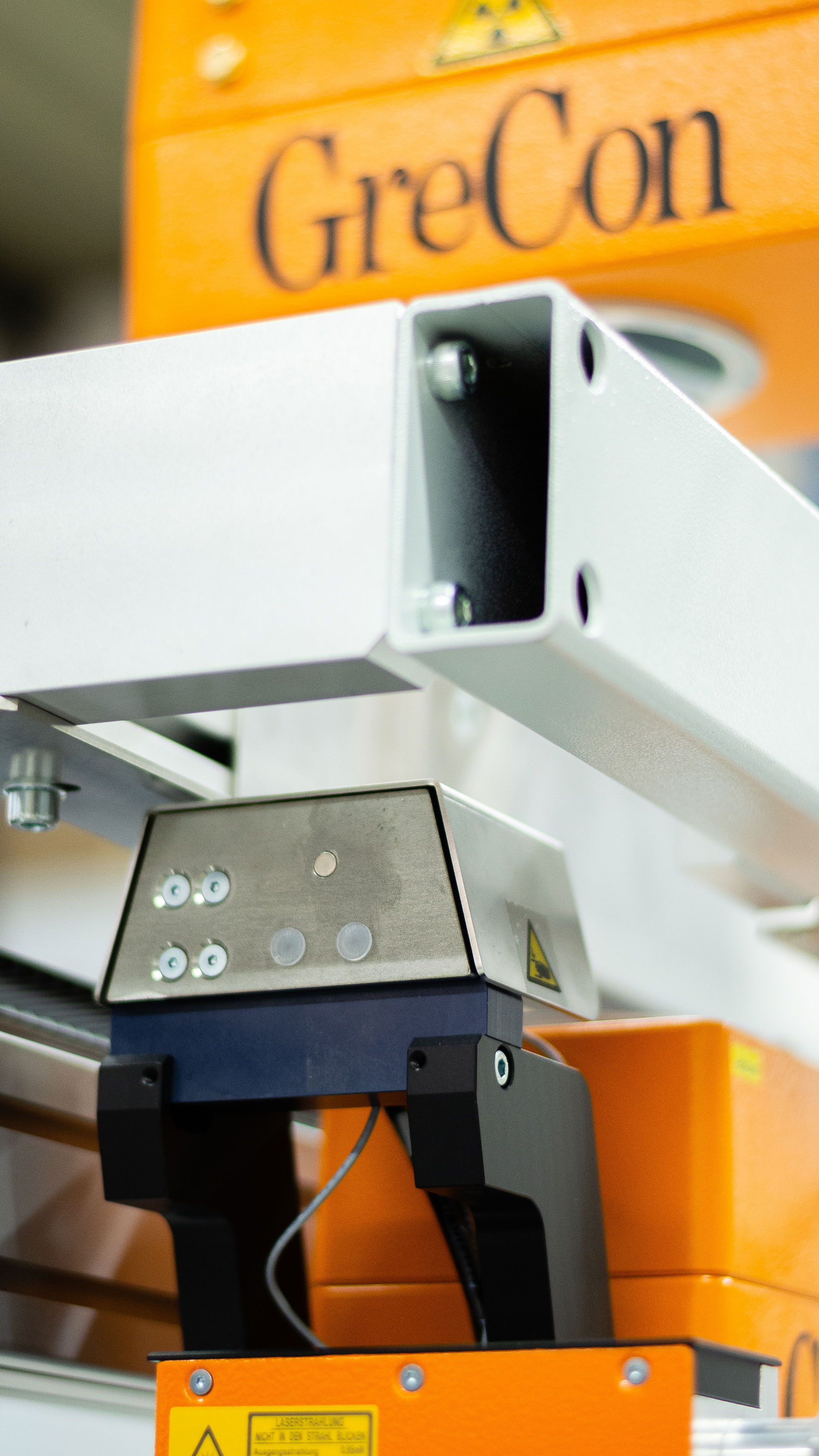

- DETECTION - GRECON SCOUT

- Spark Detector DLD 1/9 & DLD 1/9 AS

- Spark Detector FM 1/8

- Spark Detector FM 3/8

- Thermo Detector GreCon TM 1/9 Ex

- Thermo Detector GreCon TM 3/9 plus

- Hotspot detector IR

- Thermal Camera GreCon SCOUT TI

- Control Console CC 5000

- Control Console GreCon CC 7000

- System Visualisation GreCon TOUCHCLIENT

- PROTECTION - GRECON HUNTER

- Intelligent Extinguishing Module IEM

- Extinguishing Device LS

- Extinguishing Device UHS

- Diversion Gates

- Fire Traps

Industrial measurement technology from Fagus-GreCon – precision that improves processes.

- Over 50 years of experience

- Customised industry solutions

- In use worldwide

Our systems create the basis for efficient, safe and sustainable production – proven for decades in the wood-based materials industry and far beyond.

LEARN MOREMeasurement technology that sets standards in numerous industries – discover where GreCon systems make processes measurably better.

LEARN MORE- Industries

Our industry-specific solutions form the basis for successful measurement technology applications in your company.

LEARN MORE

- BUILDING MATERIALS

- Insulation Industry

- PROCESSING

- Nonwoven Industry

- Products

Your requirement. Our solution. Discover measurement technology that suits your process – precise, reliable and tried and tested.

LEARN MORE

- BELTVIEW

- BOARDCONTROL XL

- BOARDSCALE

- CHIPINSPECTOR

- DELAMINATIONCONTROL

- DENSITYPROFILER

- EDGEINSPECT

- FIBERVIEW

- FORMATOR

- GASANALYSER

- LENGTHCONTROL

- MATCONTROL

- MOISTURECONTROL

- PARTICLEVIEW

- THICKNESSCONTROL

Because success requires trust: GreCon offers installation, maintenance, remote support and more – worldwide, efficiently and reliably. Discover our services now.

LEARN MOREFagus-GreCon – Innovation is a tradition at our company!

For over 100 years, we have been developing technologies that make industrial processes safer, more precise and more efficient – worldwide, at home in a UNESCO World Heritage Site.

Since its founding in 1911, the company has set standards through groundbreaking inventions and developments.

LEARN MOREDiscover how companies worldwide use Fagus‑GreCon solutions to make production processes safer, more efficient and more reliable.

LEARN MOREOur Commitment to Society: Learn More About Our CSR Activities

- Environmentally Friendly Production

- Social Engagement

- Partnerships for Sustainability

Fagus-GreCon is aware of its responsibility and actively works toward a better future.

Fagus-GreCon at international trade fairs and events: Find out where you can meet us in person in the near future.

- International trade fairs

- Trade conferences

- Customer events

Visit us at a trade fair near you and find out about our latest innovations.

LEARN MOREWelcome to our news section!

Stay informed about the latest developments at Fagus-GreCon Greten GmbH & Co. KG.

- interesting updates

- current trends

- important news

All compiled for you in one place.

LEARN MOREFagus-GreCon – A Family-Owned Company with Tradition.

- Operating Globally

- Diverse and Dynamic

- Future-Oriented

As a family-owned business, we place great value on a supportive atmosphere and long-term relationships. Our employees are part of the Fagus-GreCon family and play a vital role in our success.

Our benefits combine modern working environments with tradition

- Individual support

- Healthy and safe

- Strong together

We create conditions that enable development and promote cohesion – today and in the future.

LEARN MOREAre you looking for a professional challenge in an environment with a strong sense of team spirit and a clear set of values?

LEARN MOREFrom talent to specialist or manager. We offer graduates the right career plan – before, during and after their studies.

LEARN MOREApprenticeships are a tradition at our company! Start your professional future today with top-notch support and numerous development opportunities.

LEARN MORE