Welcome to Fagus-GreCon - preventive fire protection for your company.

- Our solutions

- Components

- Our service

Do you have questions about our solutions, industries and areas of application? Get to know Fagus-GreCon and see for yourself. Preventive fire protection also protects your company's assets.

LEARN MOREOur fire protection solutions can be used in various industries and applications - including for your requirements.

LEARN MORE- Industries

Our industry-specific solutions form the basis for successful measurement technology applications in your company.

LEARN MORE

- CHEMICALS

- Chemical Industry

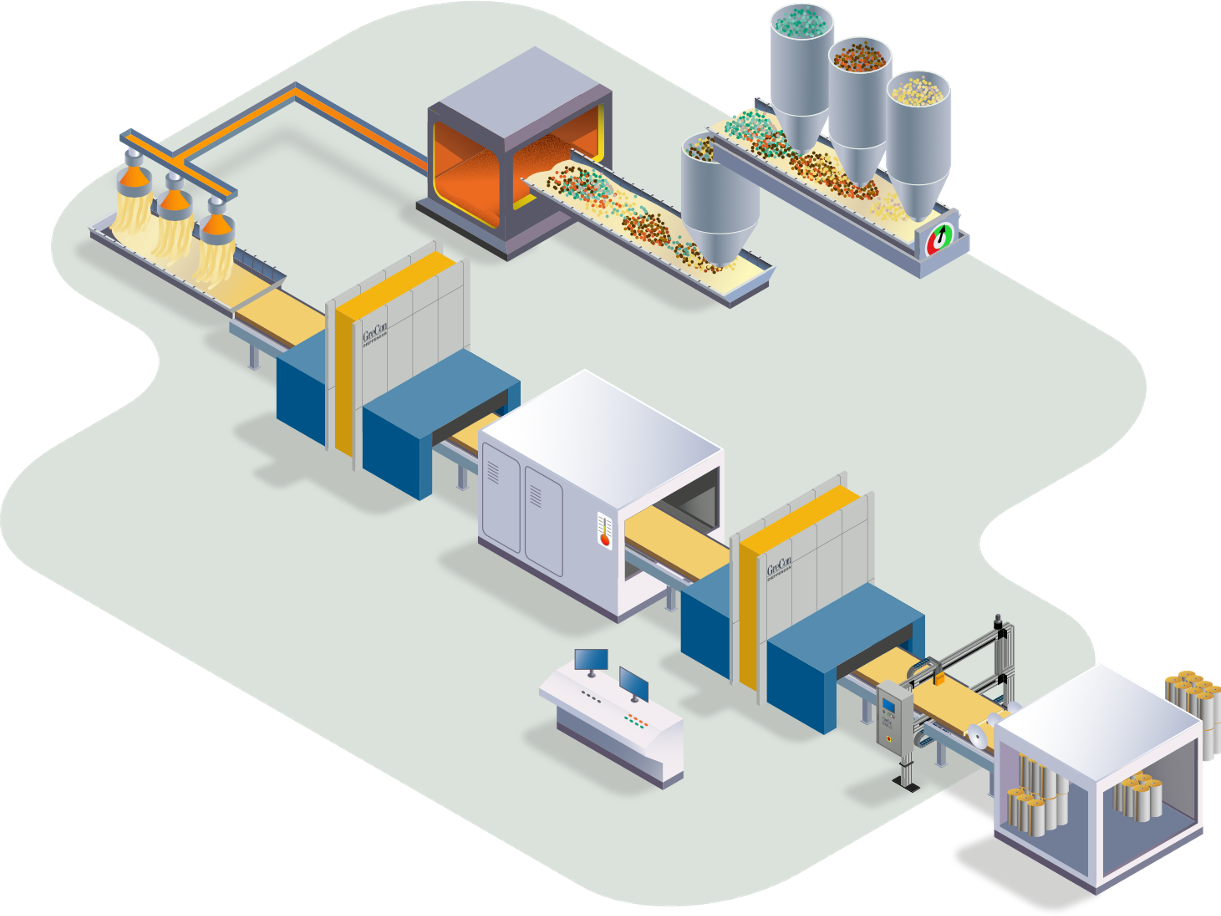

- WOOD-BASED MATERIALS

- MDF Industry

- OSB Industry

- Pellet Industry

- Particle Board Industry

- Plywood Industry

- Power Plant Industry

- FOOD

- Food Industry

- Animal Feed Industry

- Coffee Industry

- Cocoa Industry

- Sugar Industry

- METALS

- Metallindustrie

- Automotive Industry

- RECYCLING

- Recycling Industry

- Tire Recycling

- PROCESSING

- Furniture Industry

- Paper Industry

- Textile Industry

- Nonwoven fabrics

- DETECTION - GRECON SCOUT

- Spark Detector DLD 1/9 & DLD 1/9 AS

- Spark Detector FM 1/8

- Spark Detector FM 3/8

- Thermo Detector GreCon TM 1/9 Ex

- Thermo Detector GreCon TM 3/9 plus

- Hotspot detector IR

- Thermal Camera GreCon SCOUT TI

- Control Console CC 5000

- Control Console GreCon CC 7000

- System Visualisation GreCon TOUCHCLIENT

- PROTECTION - GRECON HUNTER

- Intelligent Extinguishing Module IEM

- Extinguishing Device LS

- Extinguishing Device UHS

- Diversion Gates

- Fire Traps

Industrial measurement technology from Fagus-GreCon – precision that improves processes.

- Over 50 years of experience

- Customised industry solutions

- In use worldwide

Our systems create the basis for efficient, safe and sustainable production – proven for decades in the wood-based materials industry and far beyond.

LEARN MOREMeasurement technology that sets standards in numerous industries – discover where GreCon systems make processes measurably better.

LEARN MORE- Industries

Our industry-specific solutions form the basis for successful measurement technology applications in your company.

LEARN MORE

- BUILDING MATERIALS

- Insulation Industry

- Products

Your requirement. Our solution. Discover measurement technology that suits your process – precise, reliable and tried and tested.

LEARN MORE

- BELTVIEW

- BOARDCONTROL XL

- BOARDSCALE

- CHIPINSPECTOR

- DELAMINATIONCONTROL

- DENSITYPROFILER

- EDGEINSPECT

- FIBERVIEW

- FORMATOR

- GASANALYSER

- LENGTHCONTROL

- MATCONTROL

- MOISTURECONTROL

- PARTICLEVIEW

- THICKNESSCONTROL

Because success requires trust: GreCon offers installation, maintenance, remote support and more – worldwide, efficiently and reliably. Discover our services now.

LEARN MOREFagus-GreCon – Innovation is a tradition at our company!

For over 100 years, we have been developing technologies that make industrial processes safer, more precise and more efficient – worldwide, at home in a UNESCO World Heritage Site.

Since its founding in 1911, the company has set standards through groundbreaking inventions and developments.

LEARN MOREOur Commitment to Society: Learn More About Our CSR Activities

- Environmentally Friendly Production

- Social Engagement

- Partnerships for Sustainability

Fagus-GreCon is aware of its responsibility and actively works toward a better future.

Fagus-GreCon at international trade fairs and events: Find out where you can meet us in person in the near future.

- International trade fairs

- Trade conferences

- Customer events

Visit us at a trade fair near you and find out about our latest innovations.

LEARN MOREWelcome to our news section!

Stay informed about the latest developments at Fagus-GreCon Greten GmbH & Co. KG.

- interesting updates

- current trends

- important news

All compiled for you in one place.

LEARN MOREFagus-GreCon – A Family-Owned Company with Tradition.

- Operating Globally

- Diverse and Dynamic

- Future-Oriented

As a family-owned business, we place great value on a supportive atmosphere and long-term relationships. Our employees are part of the Fagus-GreCon family and play a vital role in our success.

Our benefits combine modern working environments with tradition

- Individual support

- Healthy and safe

- Strong together

We create conditions that enable development and promote cohesion – today and in the future.

LEARN MOREAre you looking for a professional challenge in an environment with a strong sense of team spirit and a clear set of values?

LEARN MOREFrom talent to specialist or manager. We offer graduates the right career plan – before, during and after their studies.

LEARN MOREApprenticeships are a tradition at our company! Start your professional future today with top-notch support and numerous development opportunities.

LEARN MORE